Most milk plants separate milk for standardization or the obtain cream for bottling purpose and skim milk for butter milk and cottage cheese.

A layer of cream will form on the top of fresh milk, as it comes from cow, if it is allowed to stand for twenty or thirty minutes. This known as gravity creaming and it was very important prior to the invention of the cream separator. For many years it was customary to heat milk to 85 to 95 °F separation, because at this temperature the difference in density between the fat and skim milk is greatest and results in the most efficient separation of fat from skim milk.

Cream is separated from milk in a cream separator. Cream separator is a heavy metal bowl spinning at a very high speed which sediments the skim milk phase of incoming milk toward the wall of the bowl and displaces the cream inward along the centre of the bowl.

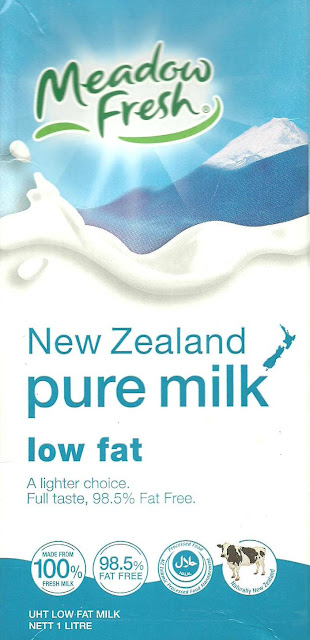

The cream and skim milk can then be recombined in desired ratios to obtain low-fat, light and whole milk with 1%, 2% and 3.25% fat respectively. This standardization usually is performed in a continuous manner.

Separation of fat or cream from milk

Understanding Class III Recalls: Ensuring Compliance and Consumer Confidence

-

A Class III product recall involves the removal or correction of a product

that fails to meet regulatory standards but does not pose a significant

risk to ...